View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor |

| Type | Casting Mold |

| Material | Metal, Steel |

| Certification | ISO9001:2008 |

| Click to view more | |

Product Details

Condition

New

Warranty

1yrs

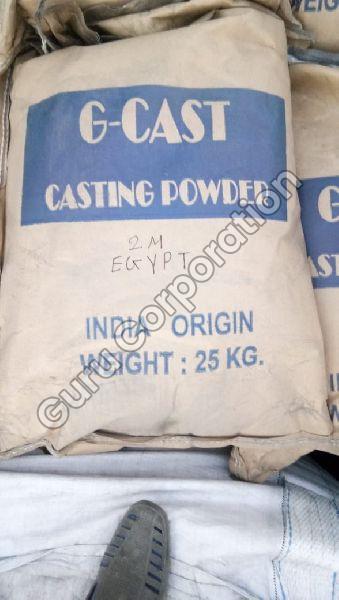

Country of Origin

India

Packaging Size

25 Kg

Surface of Application

Creating Mould

Color

Black

Physical State

Powder

Purity

90%

Product Code

02020

Port

MUNDRA

Payment Terms

L/C, T/T

Delivery Time

PROMPT

Packaging Details

We Are Manufacturer Of This Flux:

Casting Powder forms a good lubricating film on the surface of mould not allowing solidifying metal adhesion to the mould.

Casting Powder provides easy and fast solidification of metal by providing high rate heat removal from metal.

Casting Powder gives very good performance at elevated temperatures with the aid of its well selected additives.

Casting Powder increases the quality of metal surface.

Casting Powder is cheaper than Rapeseed/Casting Oil.

Specification:

CaO% : 30 – 35

SiO2 % : 33 – 40

Al2O3 % : 8 – 10

Na2O/K2O % : 4 – 6

C free% : 5 – 7

How It Works Casting Powder contains low melting constituents that instantly generate liquid slag, which penetrates into the gap between the mould and the solidifying shell of the billet. Casting Powder is added in small amounts and continuously over the casting duration. The melting of the Casting Powder occurs slowly in layers. Hence, the top surface of the liquid metal in the billet / slab / bloom always remains protected from the atmosphere.

Uses:

Traditionally Casting Powder is used for bloom and slab casting. Now, it is used for billet (open) casting also as an alternative to mould oil for some plants.

Casting Powder forms a good lubricating film on the surface of mould not allowing solidifying metal adhesion to the mould.

Casting Powder provides easy and fast solidification of metal by providing high rate heat removal from metal.

Casting Powder gives very good performance at elevated temperatures with the aid of its well selected additives.

Casting Powder increases the quality of metal surface.

Casting Powder is cheaper than Rapeseed/Casting Oil.

Specification:

CaO% : 30 – 35

SiO2 % : 33 – 40

Al2O3 % : 8 – 10

Na2O/K2O % : 4 – 6

C free% : 5 – 7

How It Works Casting Powder contains low melting constituents that instantly generate liquid slag, which penetrates into the gap between the mould and the solidifying shell of the billet. Casting Powder is added in small amounts and continuously over the casting duration. The melting of the Casting Powder occurs slowly in layers. Hence, the top surface of the liquid metal in the billet / slab / bloom always remains protected from the atmosphere.

Uses:

Traditionally Casting Powder is used for bloom and slab casting. Now, it is used for billet (open) casting also as an alternative to mould oil for some plants.

We Are Manufacturer Of This Flux:

- Casting Powder forms a good lubricating film on the surface of mould not allowing solidifying metal adhesion to the mould.

- Casting Powder provides easy and fast solidification of metal by providing high rate heat removal from metal.

- Casting Powder gives very good performance at elevated temperatures with the aid of its well selected additives.

- Casting Powder increases the quality of metal surface.

- Casting Powder is cheaper than Rapeseed/Casting Oil.

Specification:

- CaO% : 30 – 35

- SiO2 % : 33 – 40

- Al2O3 % : 8 – 10

- Na2O/K2O % : 4 – 6

- C free% : 5 – 7

How It Works Casting Powder contains low melting constituents that instantly generate liquid slag, which penetrates into the gap between the mould and the solidifying shell of the billet. Casting Powder is added in small amounts and continuously over the casting duration. The melting of the Casting Powder occurs slowly in layers. Hence, the top surface of the liquid metal in the billet / slab / bloom always remains protected from the atmosphere.

Uses:

- Traditionally Casting Powder is used for bloom and slab casting. Now, it is used for billet (open) casting also as an alternative to mould oil for some plants.

Looking for "Continuous Mould Fluxes Casting Powder" ?

Kilogram

Explore More Products